Silicon carbide

Silicon carbide is an important industrial material, produced by the reaction of quartz sand and graphite at high temperatures. It has extremely high hardness and heat resistance, widely used in abrasives, cutting tools, ceramic materials, electronic devices, and ceramic coatings. Globally, silicon carbide finds extensive applications in industries such as automotive manufacturing, aerospace, electronics, energy, and metal processing. With the development of industrial technology and increasing demand, the application of silicon carbide continues to expand and deepen.

CBN

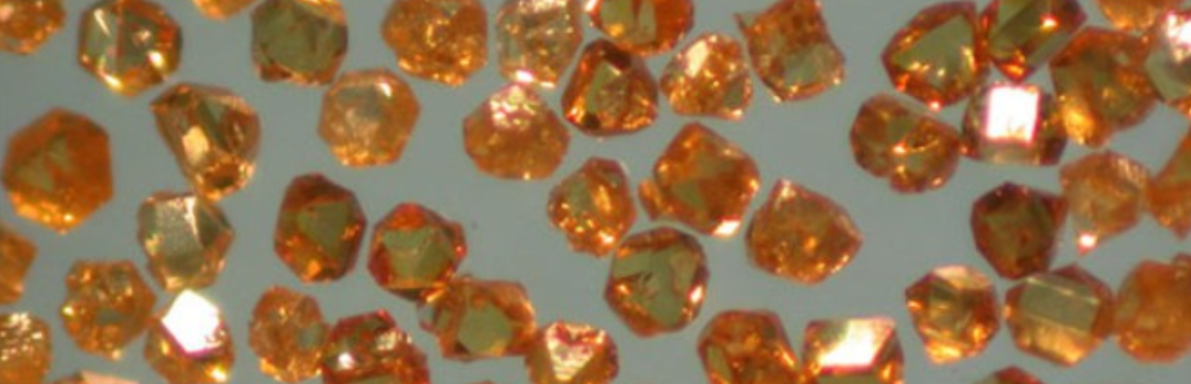

Cubic Boron Nitride

Cubic boron nitride has excellent properties such as high hardness, thermal stability and chemical inertness, as well as good red, transparent appearance and wide band gap width. Its hardness is only that of diamond, but its thermal stability is much higher than that of diamond, and it has significant chemical stability to iron-based metal elements. The grinding performance of cubic boron nitride grinding tools is not only able to process difficult-to-grind materials, improving productivity, but also effectively improving the grinding quality of workpieces.

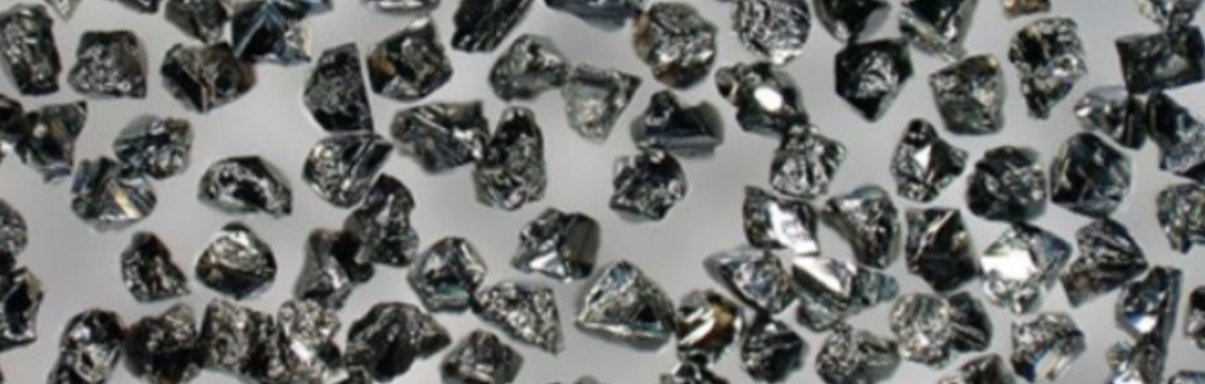

Diamand

Man-made diamonds, also called synthetic diamonds or industrial diamonds, are essential in metalworking due to their extreme hardness and wear resistance.

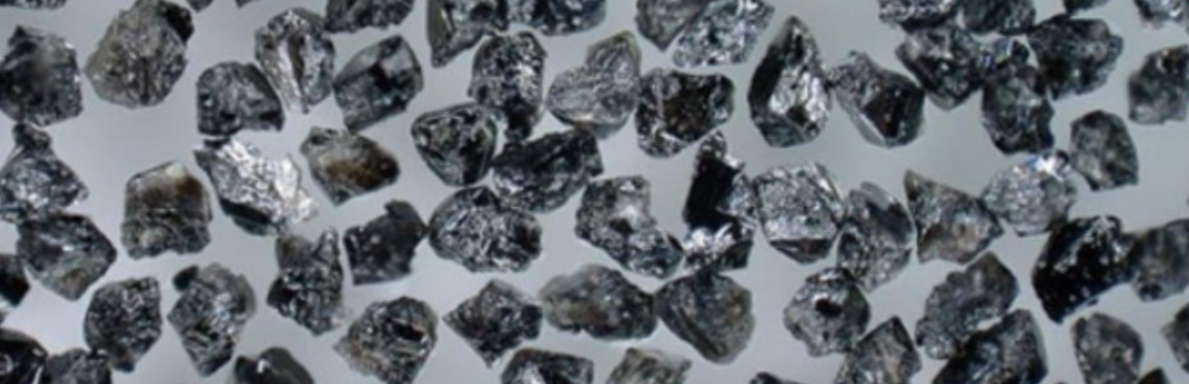

Corundum

also known as sapphire or ruby, is a versatile gemstone and industrial mineral. In industry, corundum is primarily used as an abrasive due to its hardness and durability, making it highly effective. It is used in the production of grinding wheels, sanding belts, and sandpaper in metalworking, woodworking, and glassworking. Additionally, corundum is used as a component of ceramics and refractory materials, due to its high melting point and resistance to chemical substances.

Our products

The sanding discs are specially designed for precise fine sanding and spot repair. With a grit range from P800 to P3000 and a diameter of 32 mm, they are excellent for wet sanding. These unperforated film discs offer high efficiency in removing dust particles from topcoats and clear coats.

Our sanding discs are made up of abrasive net, foam center, and a hook-and-loop backing. The innovative net structure allows water and air to freely move around the abrasive grains, enabling nearly dust-free sanding. This makes them ideal for high-gloss paints, mineral materials, and gel coats. Additionally, they offer high flexibility to achieve quick and smooth surface treatment, even on contours. Another advantage of these sanding discs is the acceleration of polishing processes.

We are here

Our range includes various abrasives and raw materials used in metalworking, woodworking, and glass processing. We cordially invite you to inquire with us and request samples.

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.